|

| February 07, 2017 | Volume 13 Issue 05 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

New patent for packaging design leads to safer ammunition storage

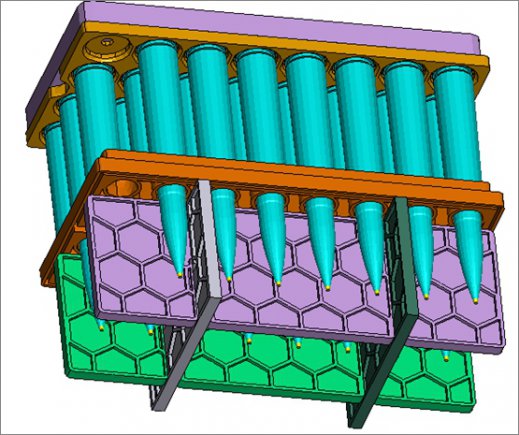

A ridged-plastic dunnage was designed to improve support of ammunition during drop and vibration scenarios. [Photo Credit: U.S. Army]

By Eric Kowal, Picatinny Arsenal

Five Picatinny Arsenal (NJ) employees received a U.S. patent last year for an improved packaging design for the 30-mm x 173-mm family of ammunition.

The previous packaging was found inadequate in protecting the ammunition throughout the U.S. Army's rigorous lifecycle requirements, thus prompting the need for a new design.

Often, 30-mm ammunition is used as an anti-materiel or armor-piercing round, which can be effective against armored vehicles as well as fortified bunkers. But, due to the inadequate packaging, links and tips of the projectiles were being damaged during a 7-ft containerized drop, which resulted in failed safety-confirmation testing.

The new, ridged-plastic dunnage was designed to improve support of the ammunition during drop and vibration scenarios. The patent, D754276, was granted on April 19, 2016.

Three current and two former employees from the U.S. Army Armament Research, Development and Engineering Center are named on the patent. The current employees are Alan Cohen, Christopher Griffith, and Jason Runell. Niral Patel and Ricardo Villela have since moved on.

"Our design is a lightweight, collapsible, plastic internal support system for 30-mm x 173-mm ammunition," said Runell, Competency Manager, Packaging Division. "It fits within an M592 rectangular steel ammunition container. The intent was to design a more robust and supportive dunnage system since the existing system failed to meet our requirements, leading to damaged ammunition.

The honey-combed stand-off in this new design is completely collapsible. [Photo Credit: U.S. Army]

"We succeeded in creating an improved system that sufficiently protected our ammunition, and we eventually passed safety confirmation testing," Runell explained. "In addition, we designed-in features that made the system less expensive than the previous system. These features included a collapsible, lightweight honey-comb stand-off. This new stand-off made manufacturing, shipping, and pack-out more efficient."

The design was inspired by the existing, 25-mm dunnage system designed in the 1990s by Greg Farbanish, a current Picatinny employee.

Similarities include a glass-reinforced nylon support plate designed to capture each projectile at the cartridge case shoulder. However, several differences made the new design unique.

The honey-combed stand-off in this new design is completely collapsible and can snap together without the use of tools.

"This makes shipping these parts very efficient. It also decreases assembly costs at the manufacturer and the load plant," said Runell.

Challenges

"When designing plastic components that have to survive shock and vibration at temperature extremes of -65 degrees Fahrenheit and +160 degrees Fahrenheit, there is no commercially available data with regard to mechanical properties at these temperatures. This made material selection rather challenging," Runell said.

"We learned, from this point forward, that we would have to create our own database for plastic mechanical properties at temperature extremes, and have since gathered stress/strain data for a multitude of plastic materials at hot and cold temperature extremes. This data is used for material screening and conducting modeling and simulation as accurately as possible," Runell said.

Published February 2017

Rate this article

View our terms of use and privacy policy